One of the best features for UPMC PPR system is the easy and ratability of installation.

UPMC system components are joined by simple-to-use fusion-welding techniques. Pure and consistent resins of the highest quality, used in the manufacture of our components, ensure reliable and repeatable welding over and over again. No matter where or when, each junction can be joined in merely a few seconds.

THERMO FUSION WELDING OF UPMC PPR

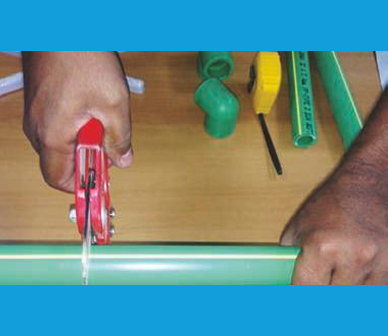

STEP 1:

Cut UPMC pipe to the required length using a cutter, mark the welding depth on the pipe, ensure that the indicator light on the welding tool signals that tool is hot enough (240˚ C) for welding.

STEP 2:

Push UPMC pipe and fitting into welding adaptors, applying even strength at both ends. Do not twist or turn the pipe and fittings while pushing. Wait until heating time is reached. Attached table NO (x) for necessary information.

STEP 3:

When welding time is reached, remove both pipes and fitting together, again without twisting or turning while pulling out of the welding adaptor. Almost immediately, push both pipe and fitting together until the depth is reached. It is possible to adjust the joints for more than 5 degrees during this time. Thus the fusion process is completed.